|

Outstanding Milestones/ Research Evaluation Committee Approved Technologies

|

|

Agro-Processing Complexes: Rural entrepreneurship through suitable agro-processing models/complexes is essential to increase the income of the farmers, provide significant employment opportunities to the rural youth and reduce huge amount of post harvest losses. These include a 5 qtls per hour Atta chakki for whole flour, a mini rice mill processing 250 kg/h, an oil expeller unit processing 100 kg/h, a honey processing unit completing 50 kg/batch in one hour, a spice grinding unit for turmeric and red chilli, a jaggery processing unit handling 10 qtls/h, a feed mill, and a dal processing and packaging unit. The estimated cost of machinery ranges from Rs. 15 to 25 lakh. The department has designed a suitable layout requiring a minimum space of 50 ft X 60 ft to accommodate the machines, although additional open space is needed for vehicle movement. A total electric load of 25 KW is sufficient to operate the machines. Such unit creates employment opportunities for 2-5 individuals in rural areas.

|

|

|

PAU Portable maize dryer: A portable maize dryer has been developed as per international norms to dry maize grain from a moisture level 25% to 15% in 8-10 hours. This cross-flow dryer has three pass, indirect type diesel fired heating system to maintain the grain temperature of 45?C for seed and 60?C for commercial purpose. The dryer is capable of drying maize grain @ 1 – 1.5 % per hour consuming max 4 litres/h of diesel initially for 1 hr. A provision of heat recovery from flue gases ensures higher fuel efficiency with reduced diesel consumption of approximately 2 litres/hr later on. The dryer can be operated both with tractor PTO and electricity. One each skilled and unskilled labour is required to operate this dryer.

|

|

|

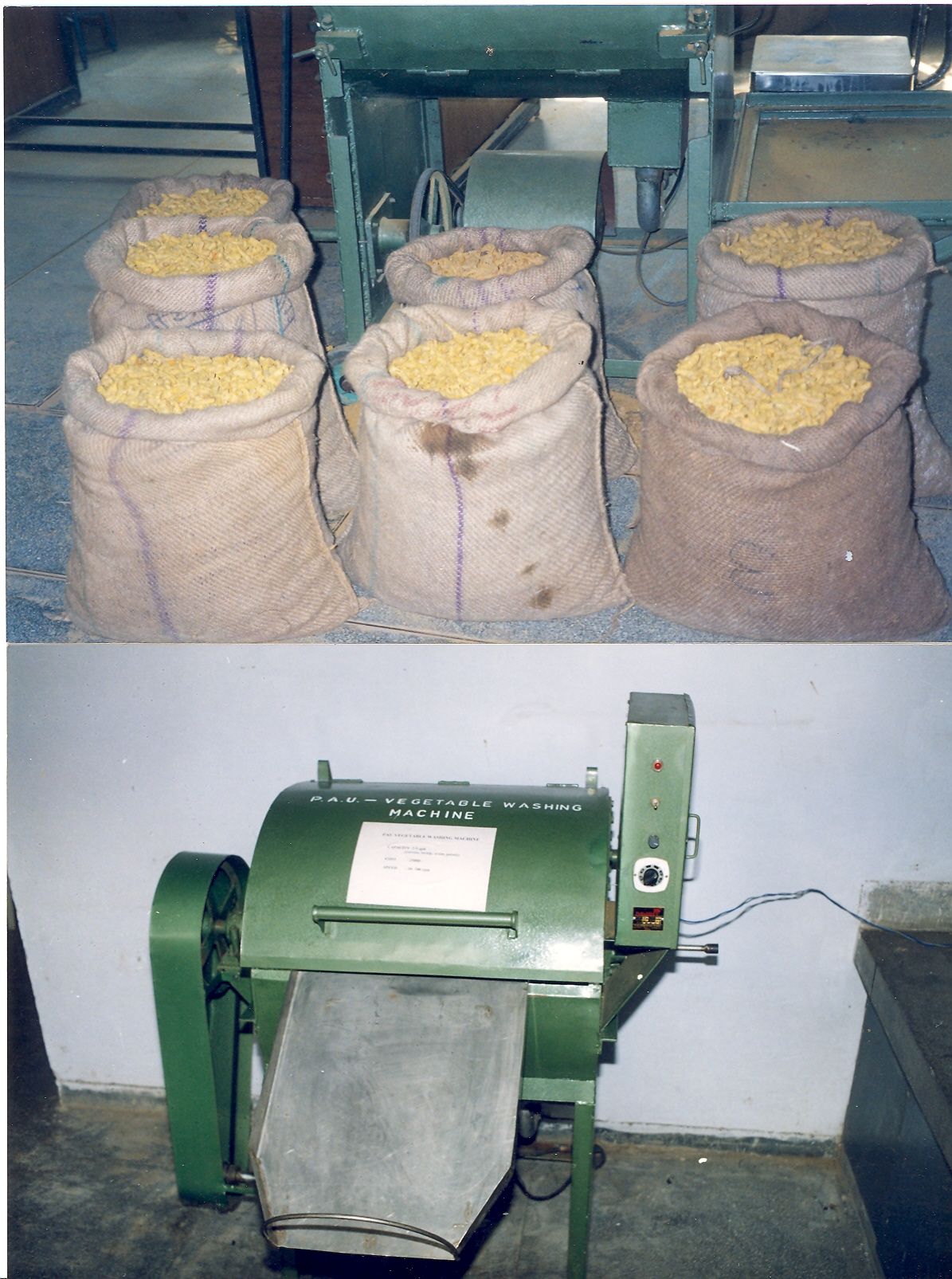

Horticultural Produce Washing Machine: A stainless steel, portable, 1 hp, electric power operated rotary drum type washing machine (1-6 qph, capacity) has been developed to wash a wide range of fruit and vegetables (carrot, potato, radish, turnip, ginger, okra, tomato, spinach, turnip, kinnow and pears). Washing cost is Rs.1-10 per qtl depending on the crop and the model of the machine used. This machine costs Rs. 90,000 and can be used both by the producer and processor.

|

|

|

Honey heating-cum filtration Unit: This is a fully mechanized Honey Filtration Unit with separate heating and filtration arrangements having two separate sensors for sensing and controlling the temperature of heating water as well as honey in the main chamber. It consists of two sections; the top heating section and the lower filtering section. In order to have uniform temperature profile throughout the heated honey an electrically operated six fins stirrer stirring the sample at optimum speed as and when required. The filtration section consists of a strainer of 200 mesh size which could be detached for cleaning, a valve for releasing the heated honey to pass through the filtration unit and a pump (operated by 0.5 h.p motor) to flush out the honey at the rate of 10kg/min. The operator is comfortable while working with it. One person is required for its operation. The cost of honey heating-cum-filtration machine is approximately Rs.90, 000 which can process approximately 2 qtls of honey per day.

|

|

|

Turmeric washing and polishing machine: Turmeric rhizomes can be mechanically washed as well as polished in a, portable, electric power (1 hp) operated, rotary drum type turmeric washing and polishing machine. The machine when operated at optimum rotational speed for optimum time can wash 2.5-3.0 qph of turmeric rhizomes. At optimum performance parameters, i.e. 40 rpm for 5 min. there is no bruising in turmeric rhizomes, with a microbiological washing efficiency of 91%. The same machine can be used for polishing turmeric with some modifications. The capacity of turmeric polishing machine is 1 qph. The optimum performance parameters for polishing are 40 rpm for 20 minutes at which the desirable olive yellow colour is obtained and the surface becomes smooth. This machine costs Rs. 80,000-1, 00,000/- (and can be used both by the producer and processor).

|

|

|

Brick and Sand Store: A simple structure of double wall of bricks, sand and cement of size 1.9 m X 1.3 m and a height of 0.6 m have been developed for domestic storage of fruits and vegetables. This structure has sand in two walls. The sand is kept wet by adding water periodically which is allowed to evaporate causing cooling in the interior chamber. The structure is covered from the top with a net and a wet jute bag is placed over it. Capacity of the structure is approx. 30 to 40 Kg and temperature reduction upto 10-15° C can be achieved.

|

|

|

Electric-cum-Battery Heated Uncapping Knife: In order to make the uncapping process more effective an electric-cum-battery heated uncapping knife working both on AC as well as 12 V DC can uncap one frame in 20-22 seconds. Its performance is better in comparison to the conventional knife in respect of ease of operation and timeliness.

|

|

|

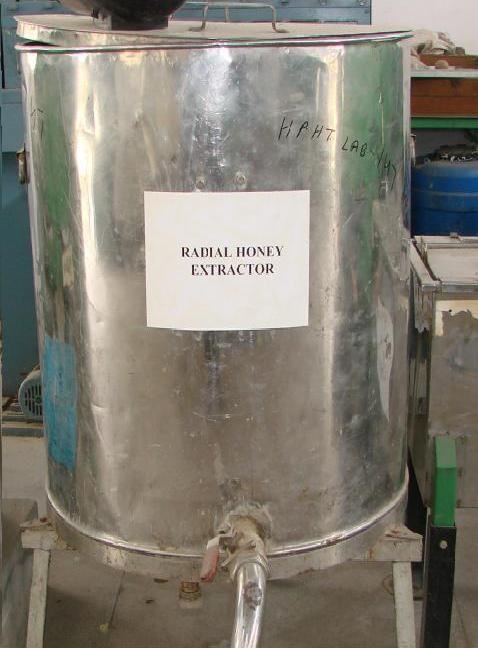

Radial honey extractor: The Power-cum-hand operated eight frame radial honey extractor made up of stainless steel (food-grade) was designed and developed. This works efficiently at 165 rpm with the honey recovery of 192 kg/h. The initial investment is Rs. 50,000 and the running cost is Rs. 11/ q of honey.

|

|

|

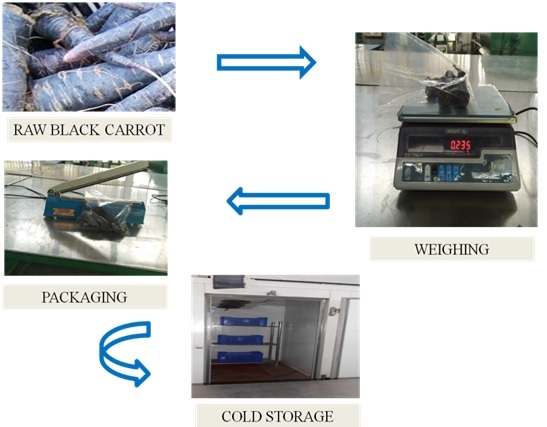

Technology for extending shelf life of fresh black carrot cv. Punjab Black Beauty by Modified Atmosphere Packaging and Storage

Packaging of fresh whole black carrot in non-perforated 150 gauge LDPE packages followed by storage at 5oC and 85±5% can extend its shelf life to 21 days for retail marketing.Packaging of fresh whole black carrot in perforated 150 gauge LDPE packages and storage at 10oC and 85±5% can extend its shelf life to 15 days for retail marketing.Storage of unpackaged black carrot at 5± 1oC and 85±5% can extend its shelf life to 12 days for retail marketing.

|

|

|

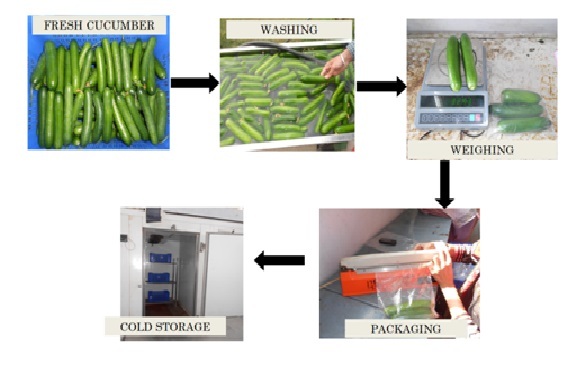

Technology for Enhancing Shelf Life of Fresh Cucumber by Modified Atmosphere Packaging and Storage: Packaging of fresh cucumber in non-perforated 150 gauge LDPE packages followed by storage at 10oC and 85±5% can extend the shelf life of varieties KUK-9, KAFKA, PBRK 4 to 28 days and MULTISTAR to 24 days for retail marketing.

|

|

|

Aloe vera leaf gel extraction machine: This machine will cut the processing cost as it’s capable of extracting large amount of gel from aloe vera leaf in small time. It saves lot of labour and can solve the problem of labour scarcity especially in aloe vera gel extraction process. The cost of the aloe vera leaf gel extraction machine is around Rs 35000. The machine is simple in operation, hazard free, made of food grade material and needs 1 hp power for operation and the operational cost per day is also very less.

|

|

|

Pilot scale plant for pectin extraction and its process optimization for kinnow and mosambi waste (peel)

The developed Pilot scale plant for pectin extraction using chemical method (HNO3/HCl) having capacity of 50 kg/batch of kinnow/mosambi peel yield 14±1 and 18±1% (d.w) pectin from kinnow and mosambi peel respectively. Optimized operational conditions of pilot plant for pectin extraction are pH of solution 2.0, temperature 74°C, extraction time 60 min and pH of solution 1.32, temperature 78.5±1°C, extraction time 60 min for kinnow and mosambi peel respectively.The developed pilot scale pectin extraction plant will be helpful for the budding entrepreneurs/processors dealing in kinnow/mosambi juice processing.

|

|

|

Mechanically Ventilated Onion Storage Structure:

The structure is made up of angle iron frame and wire mesh. The 1.25 ton onions can be filled by one person in almost 30 minutes while the structure could be emptied in 5 minutes by raising the front sliding gate. In addition to natural ventilation a provision of mechanical aeration has been provided at the base of this storage structure. Total losses in stored onions in the fabricated structure due to all reasons were observed to be 26%. The cost of storage structure is approx. Rs. 10,000/-

|

|